About us

Production profile

LINEX Sp. z o.o. is a leading manufacturer of automotive control cables on the Polish and European markets. The main company’s production concentrates on:

| • Control cables | |

| • Bowden cables i.e. accelerator, brake and clutch cables | |

| • Cables for doors, bonnet and boot opening for all makes of cars | |

| • Push-pull cables | |

| • Conduits and casings |

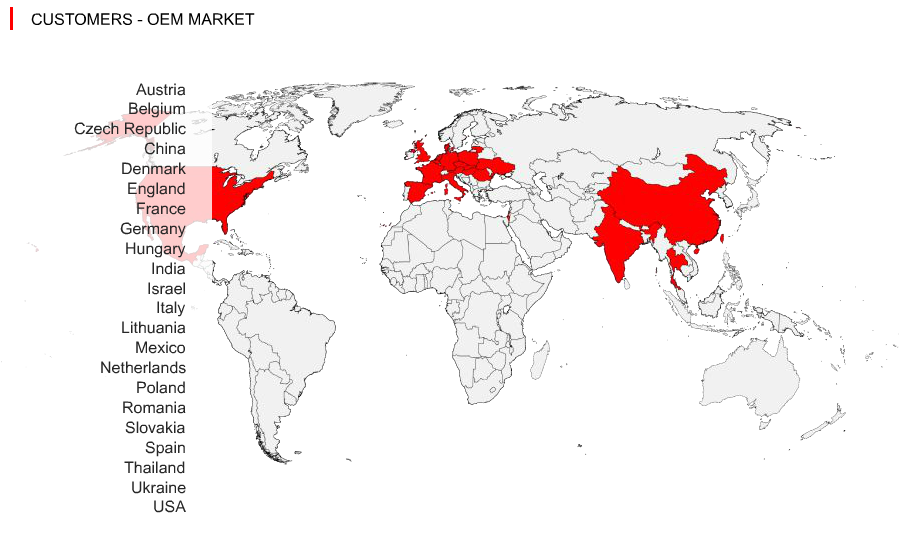

Our products are delivered to the following:

We have attained the position of the European leader on the aftermarket by offering a very wide range of products covering almost all car makes and types of vehicles, as well as by excellent quality guaranteed with IATF 16949 certificate, an attractive price level, and our dedication to constantly improve customer satisfaction.

The most important attributes of LINEX Sp. z o.o. are the following:

Thanks to them we have increased yearly the supply level and the number of projects for the OEM market. Currently, 40% of the production is delivered directly to car factories for the purpose of the first assembly for car makes such as ALFA ROMEO, ASTON MARTIN, AUDI, BMW, FIAT, GEELY, HYUNDAI, JAGUAR, KIA, LAMBORGHINI, LANCIA, MASERATI, MERCEDES-BENZ, PEUGEOT, PORSCHE, SKODA, SMART, VOLKSWAGEN, VOLVO.

In addition to the automotive industry, we manufacture and supply control cables and wires of different construction for the medical, welding, lighting, construction and even knitting markets.

Production technologies

LINEX Sp. z o.o. products’ manufacturing is based on the following production technologies:

|

|

• Zamak injection |

| • Crimping, crimping on presses, cold forming | |

| • Conduits torsion | |

| • Push-pull conduits torsion | |

| • Flexible shafts torsion | |

| • Plastic coating | |

| • Extrusion with the use of different types of materials (tubes, sleeves) | |

| • Plastic injection | |

| • Plastic overmoulding on vertical injection machines | |

| • CNC machining |

We have vast experience in the design and application of all of the above technologies. In combination with the well developed company’s machine park, which includes both traditional and modern machinery and equipment, we have obtained a very large production capacity.

Company History

LINEX history means over 50 years of business operation, when a company from a local manufacturer of steel cables has become a leading on the domestic market manufacturer of automotive control cables.

Beginning in 1963, the company has been opened by Stanislaw Kasprzycki, who in a small workshop, located in Czestochowa at Warszawska Street, on self-constructed machines has started and developed the production of semi-finished products for the production purpose of automotive control cables- steel wires, Bowden conduits and flexible shafts. In 1981, he passed to his son Wojciech Kasprzycki a well-operating workshop. Based on this solid foundation, the new owner in 1983 decided to start production and therefore to enter the market of finished automotive control cables. The selected production profile is still the primary branch of LINEX company’s business operation.

Since 1990, with the change of Polish political system, the company has been developing dynamically. A large and sudden increase in demand for its products caused the need to expand the production surface, which in 1993 resulted in the transfer of the manufacturing plant of the company together with its head office to the newly purchased building at Rejtan St. 15. This was the time when the brand was officially created and the name LINEX was given to the company.

In subsequent years, LINEX has been developing its operation, continually expanding both the range of products and entering new markets, as well as developing the infrastructure and organization, while ensuring higher standards of management, operation and quality.

The following turned out to be the mile-stones in the history of the company:

Tradition, development and quality – these three words in short describe the history of our company, which thanks to a coherent vision of its owners, their dedication to the development and consistency in the quest to achieve the highest quality of products, has made LINEX a brand recognized all across Europe.

Continuous Development

The mission of LINEX Sp. z o.o. is to produce and sell control cables and links of the highest quality, with timeliness, providing safe work conditions, and with concern for the environment. We want to be a significant company in the supply chain for the automotive industry, leading in supplying to the market of spare parts in Europe and Poland. In order to achieve this, we are dedicated to meet the needs of customers both in the small batch and large batch production. LINEX develops in accordance to the philosophy of sustainable growth, trying to be flexible and quickly respond to any market changes.

In carrying out this adopted mission, the company constantly adapts to the growing needs and requirements of customers, still increasing its potential by investing in the development of technical and technological infrastructure as well as the development of its employees.

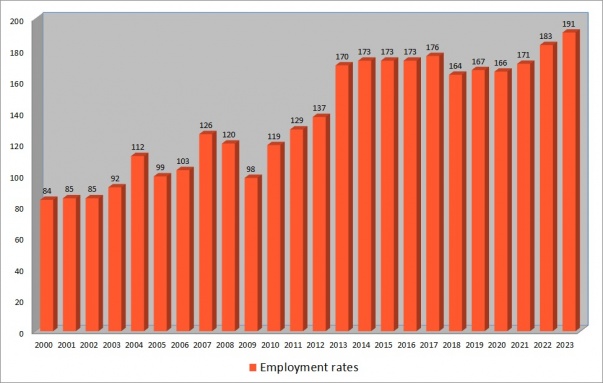

Currently LINEX Sp. z o.o. employs nearly 200 experienced employees and has facilities with a total area of almost 8000 m2, which include:

• production hall I where processes of zamak and plastic injections, coating, sleeve and tubes extrusion as well as the assembly of finished products take place

• production hall I where processes of zamak and plastic injections, coating, sleeve and tubes extrusion as well as the assembly of finished products take place

• modernly equipped office building used by the company’s administrative departments

The quality of our products is ensured by the quality management system implemented and certified in 1999 in accordance with ISO 9001:2000 standard, which has been additionally certified since 2009 for compliance with the required in the automotive industry ISO/TS 16949:2009 Technical Specification.

In 2018 Linex positively went through a certification audit, as a result of which, received PN-EN ISO 9001:2015 and IATF 16949:2016 certificates.

In order to maintain the position obtained in years of company’s operation, we put special emphasis on the following:

• Timeliness of delivery

• Excellent quality of products

• Monitoring of customer satisfaction

• Continuous expansion of product selection

• Optimization of production costs

• Increasing the qualifications of the crew

• Increasing labor productivity

• Development of technological infrastructure

Quality guarantee

Uncompromising standards of products’ quality used to be and still are one of the foundations of LINEX company's success. The quality from the beginning of the company is based on the philosophy "perfection = zero defect".

The Board of Directors of the company, having a sense of responsibility for the functionality and safety of our products, and trying to improve customer satisfaction, established in 1998 the Quality Policy. An essential condition adopted then and unchanged to this day that ensures a high quality of products is an effective and clear organization of the quality management system. In order to achieve their objectives and improve organizational efficiency and thus meet better the needs of our customers, LINEX as soon as in 1999 developed, implemented, and certified the quality management system in accordance with the requirements of ISO 9001:1998.

The growing demands of the automotive industry in terms of the need to ensure the maximum safety and the quality of supplied products, have resulted in strengthening of our pro-quality approach and an adaptation of the quality management system, already functioning in our company, to the Technical Specification ISO / TS 16949:2009 standards. We obtained a confirming certificate in 2009.

The growing demands of the automotive industry in terms of the need to ensure the maximum safety and the quality of supplied products, have resulted in strengthening of our pro-quality approach and an adaptation of the quality management system, already functioning in our company, to the Technical Specification ISO / TS 16949:2009 standards. We obtained a confirming certificate in 2009.

In 2018 Linex received the positive assessment from certification audit. The certificate confirms the compliance of the company’s Quality Management System with the PN-EN ISO 9001:2015 and IATF 16949:2016 requirements.

Today in LINEX Sp. z o.o., the quality management system covers each aspect of the company’s production operation. Starting from the recognition of customer needs, the feasibility study, through the design of the product and process, logistics and organization of production, production, supply, and ending with project management and the warranty care.

Certifications obtained by LINEX guarantee that taking care of quality of products supplied by us is a top priority of the company. Every day we strive that the efficient and effective operation of the system would give a guarantee of meeting the high and ever-increasing requirements of the market.

Certificates

Management systems

At the time when high quality, environmental and social requirements are placed upon organizations, the Management Board of LINEX Sp. z o.o., in its activities, refers to the management systems and policies given below:

- quality management system,

- quality management system in the automotive industry,

- environmental management system,

- Linex policies: Health and Safety policy, Quality Policy, Responsible Business Policy, Environmental Policy

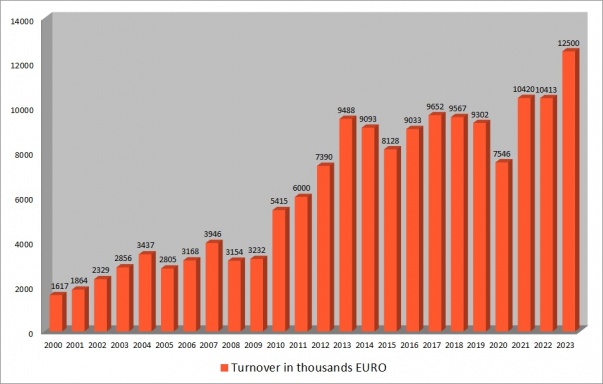

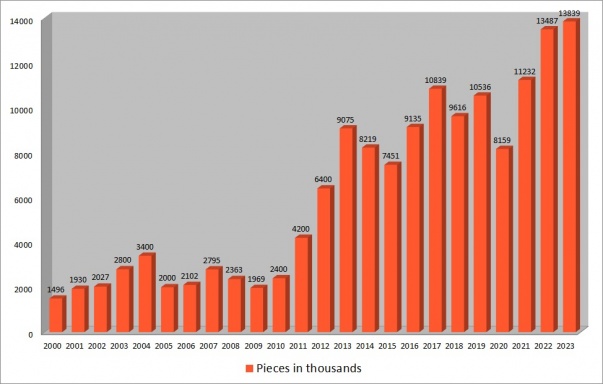

Financial and Performance Indicators

Awards and Funding

Awards:

In 2006, LINEX company received a Skills and Competencies 2005 Golden Laurel in the category Polish Company. The award is granted for the last 14 years by the Regional Chamber of Commerce in Katowice to outstanding companies, organizations and institutions.

Funding:

On the 16th of December 2013 LINEX Sp. z o.o. concluded with the Silesian Center for Entrepreneurship a contract no. UDA-RPSL.01.02.04-00-163/11-00 for the funding from the European Regional Development Fund of the investment project under the name "Increasing the competitiveness of the company through the modernization of the machine park facilities, affecting the improvement of existing products and the introduction of new ones", within the framework of the Regional Operational Programme of Silesia for 2007-2013 - Sub-measure 1.2.4 Micro, Small and Medium Enterprises.

Total Project Value: 1,882,158.10 PLN

Grant amount: 726,484.34 PLN

On the basis of the contract no. POIR.03.04.00-24-0099/20-00 concluded with the Polish Agency for Enterprise Development (PARP) on the 9th July 2020, LINEX received support from the European Union Fund in the amount of 350 303,43 PLN, within the framework of the co-financed investment project of the OPERATIONAL PROGRAMME Smart Growth, Priority Axis 3: Enterprise Innovation Support, Operation 3.4 Grants to Working Capital.

On the basis of the contract no. UDA-RPSL.03.02.00-24-04GE/20-00 concluded with the Silesian Center for Entrepreneurship on the 24th March 2021, LINEX received support from the European Regional Development Fund in the amount of 800 000,00 PLN, within the framework of the co-financed investment project of the REGIONAL OPERATIONAL PROGRAMME OF SILESIA for 2014-2020.

Project Name: Investments which aim is to maintain and increase competitiveness, maintain employment and its growth, relevant to the SARS-Covid 19 pandemic

Project Objective: Purchase of production machine and installation of photovoltaic power system

Anticipated Results: Employment growth

Project Value: 1 528 398,00 PLN

Contribution of the European Funds: 800 000,00 PLN

.'/application/images/up_arrow.jpg)